Why Choose Tube Laser Cutting?

Eliminate manual work, reduce errors, and get precision that's impossible with traditional methods

No More Manual Drilling

Stop laying them out breaking drill bits in thick-wall tube and dealing with burrs that need grinding. Our laser cuts clean, precise holes without tool wear, wandering bits, or secondary finishing work.

No More Fighting Angles

Complex miters, compound angles, and tricky cuts become simple. We handle it and - you get parts that fit perfectly the first time.

Tube Laser Benefits:

Precision: Your parts fit perfectly the first time

Speed:

Cut all angles in one setup (no repositioning) Fast turnaround on most projects Reduces your project timeline by days/weeks From drawing to finished parts faster than traditional methods

Quality: Less finishing work for you

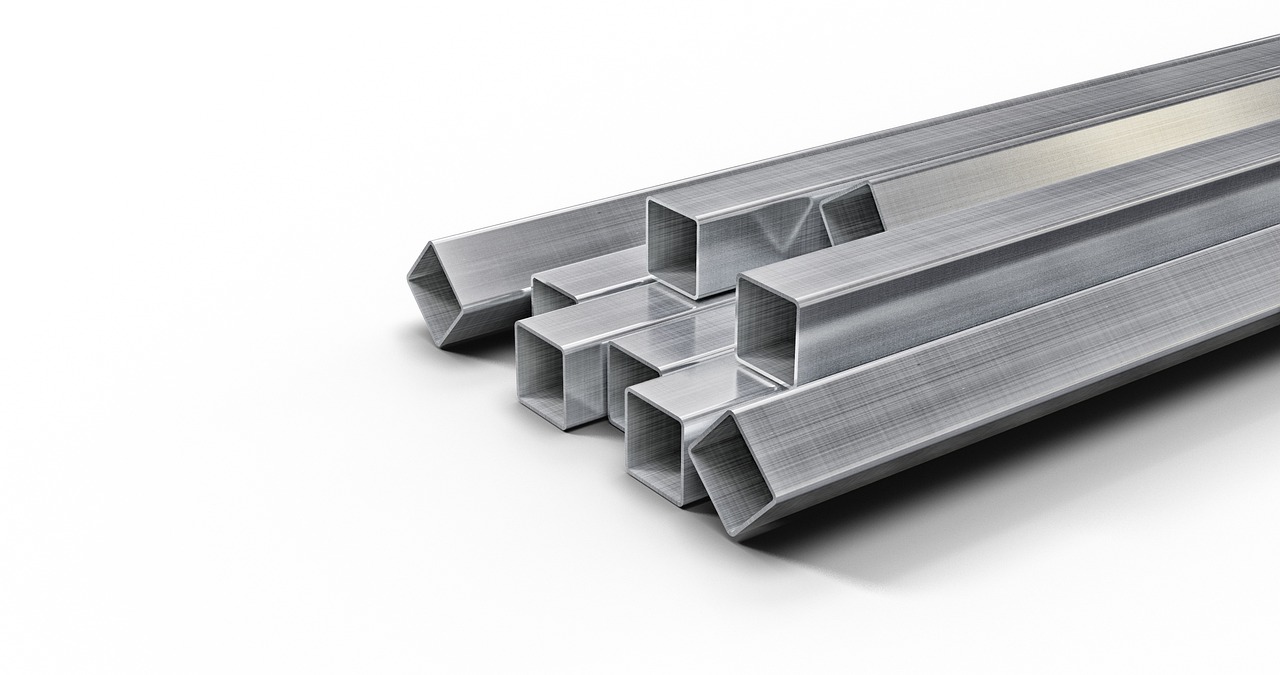

Materials and Profiles

Mild Steel

Our capabilities extend beyond the materials and profiles mentioned. Our processes are engineered to excel with these materials. Reach out to us to discuss the unique materials and thicknesses of your projects.